Stand on Big Each Stacker

Reach stacker crane is a new generation product developed for storage material equipment. It is driven by batteries.

● Horizontal handling and stacking of medium-sized goods;

● Medium to long distance handling and stacking;

Suitable for loading and unloading palletized goods in warehouses and workshops, it is the best choice for metal profiles, steel bars, wood, steel pipes, etc.

PRODUCT DETAILS

| Place of Origin: | China |

| Brand Name: | Chengli |

| Model Number: | KLR |

| Certification: | CE/ISO |

| Minimum Order Quantity: | 1 |

| Packaging Details: | Packaging supports wrapping film, wooden pallets,and wooden boxes,Choose packaging according to your needs |

| Color: | Customized |

| Payment: | T/T,L/C,D/P,D/A,MoneyGram,Western Union |

Description:

● All directions travelling, used in very narrow aisle for long material handling;

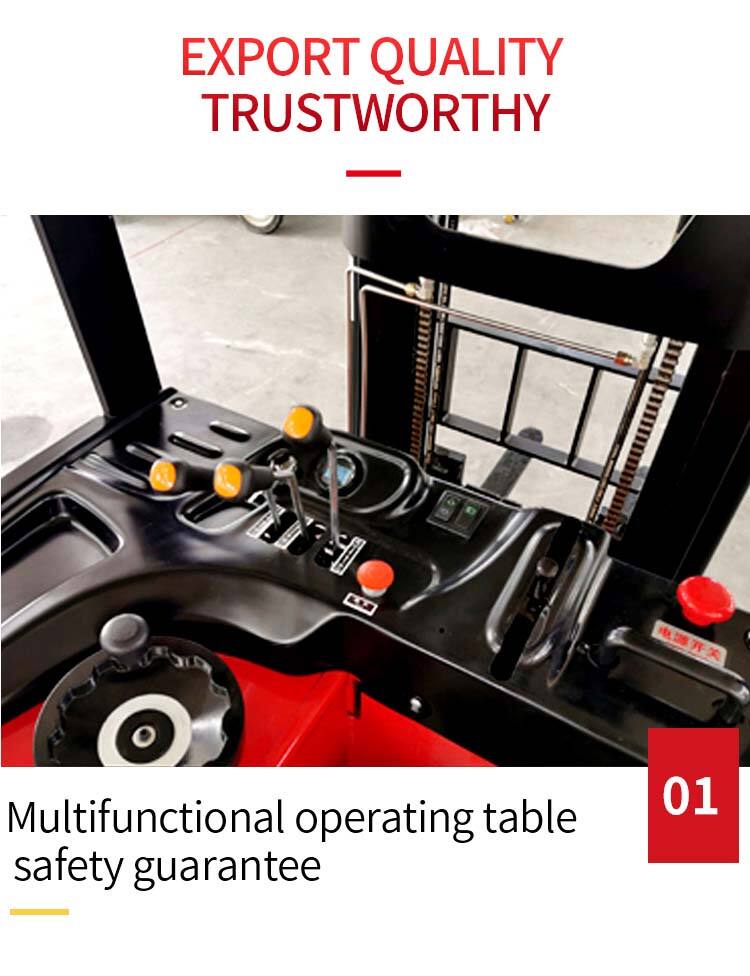

● Full AC system, electric power steering, long service life and low energy consumption;

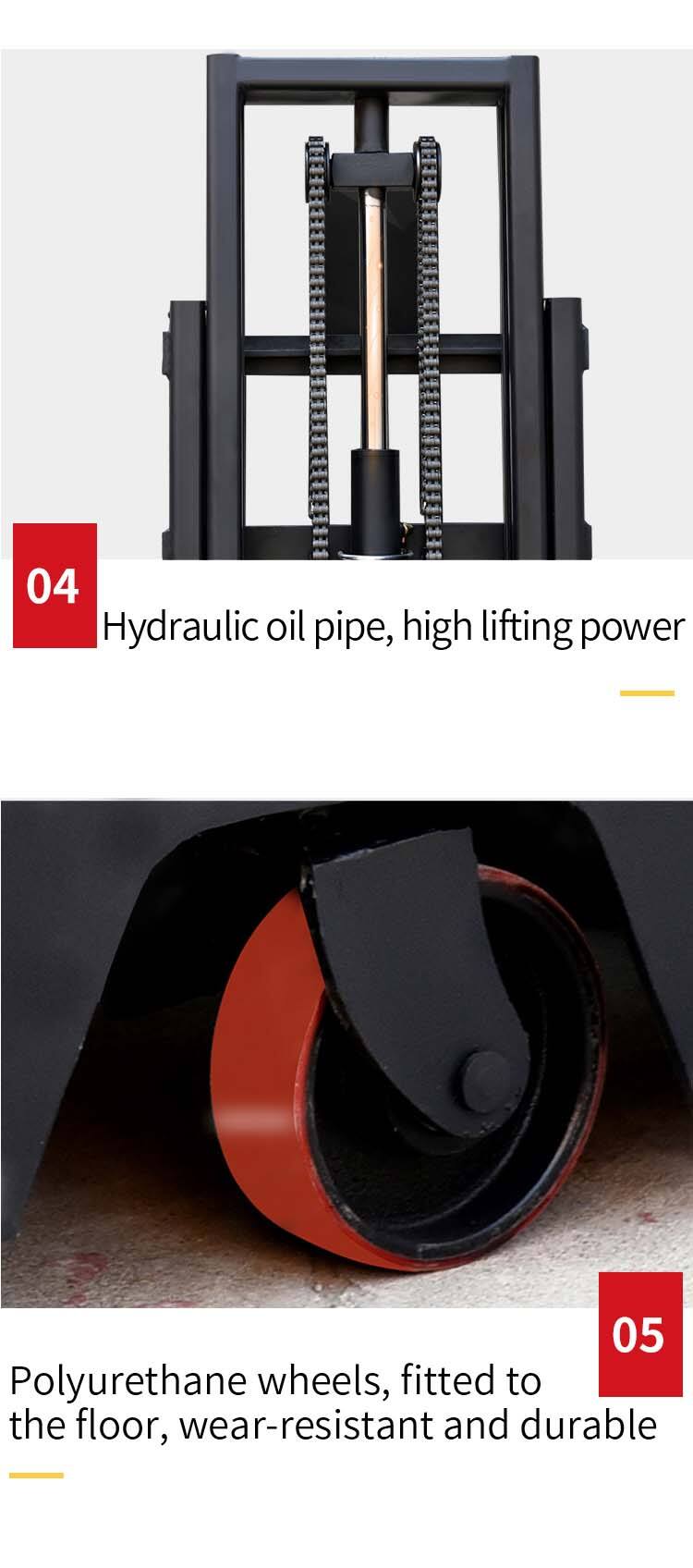

● Cast steel drive box, High strength PU tyres, driving stable, braking reliable;

● High definition drive wheel display;

● Big capacity battery.

● Controller multiple automatic protection

● Emergency reverse collision avoidance/emergency braking device

Forklifts are widely used in factories, mines, warehouses, stations, ports, airports, freight yards, distribution centers and distribution centers. They can enter the cabin, carriage, and container. They are necessary equipment for pallet and container transportation, such as loading and unloading, stacking, sorting, dismantling, and short distance handling of components, packaging, pallets, and containers.

Forklifts can also be used for bulk cargo, unpackaged cargo, large and large cargo, and short distance loading and unloading. Forklifts are not only widely used in departments such as road transportation, railway transportation, and waterway transportation, but also in departments such as material storage and transportation, postal services, etc.

Specifications

| Performance | Model | KLR15C | KLR20C | KLR25C |

| Maximum load capacity (kg) | 1500 | 2000 | 2500 | |

| load center (mm) | 500 | 500 | 500 | |

| Maximum lifting height (mm) | 3000 | 3000 | 3000 | |

| Reach length (mm) | 550 | 550 | 550 | |

| Reach length (mm) | 3/5 | 3/5 | 3/5 | |

| Travel speed (without load) (km/h) | 8 | 8 | 8 | |

| Travel speed (with load) (km/h) | 7 | 7 | 7 | |

| Lifting speed (without load) (mm/s) | 244 | 244 | 244 | |

| Lifting speed (with load) (mm/s) | 94 | 94 | 94 | |

| Lowering speed (without load) (mm/s) | 224 | 224 | 224 | |

| Lowering speed (with load) (mm/s) | 700 | 700 | 700 | |

| Gradeability (without load ) (%) | 15 | 15 | 15 | |

| Gradeability (with load ) (%) | 8 | 8 | 8 | |

| Dimensions | Service weight (with battery) (kg) | 2430 | 3020 | 3050 |

| Overall length of frame excluding fork (mm) | 1890 | 1890 | 1990 | |

| Overall length of frame including fork (mm) | 2479 | 2479 | 2579 | |

| Overall length including mast reach length (mm) | 3029 | 3029 | 3129 | |

| Overall width of frame (mm) | 1270 | 1270 | 1270 | |

| Overall height when mast lowered to lowest (mm) | 2084 | 2084 | 2084 | |

| Overall height when mast lifted to highest (mm) | 4045 | 4045 | 4045 | |

| Wheelbase (mm) | 1510 | 1510 | 1610 | |

| Fork size (mm) | 1070* 35* 100 | 1070* 40* 100 | 1070* 40* 120 | |

| Adjustable range of fork outside width (mm) | 210-820 | 210-820 | 250-820 | |

| Fork height when fork lowered to lowest (mm) | 60 | 65 | 65 | |

| Min ground clearance (mm) | 30 | 30 | 30 | |

| Theoretical Width of minimum aisle for right-angle stacking (mm) | 2673 | 2673 | 2772 | |

| Minimum turning radius (mm) | 1783 | 1783 | 1882 | |

| Overhead guard height (mm) | 2190 | 2190 | 2190 | |

| Tire | Front wheel (mm) | 267* 114 | 267* 114 | 267* 114 |

| Drive wheel (mm) | 340* 130 | 340* 130 | 340* 130 | |

| Wheel material | polyurethane | |||

| Electrical components | Drive motor type | AC series motor | ||

| Rated output (kw) | 5 | 5 | 5 | |

| Hoist motor type | DC series motor | |||

| Rated output (kw) | 6.3 | 6.3 | 6.3 | |

| Battery | Voltage (V) | 48 | 48 | 48 |

| Capacity (AH) | 325 | 440 | 440 | |

| Weight (kg) | 600 | 740 | 740 | |

Advantage

1. We have been specializing in the research and development and production of forklifts for 21 years. As the source manufacturer, we produce and sell our own forklifts with excellent quality and affordable prices

2. Sufficient stock, fast delivery speed, and product customization support

3. Rigorous material selection, thickened steel, and increased load-bearing capacity

4. We have a fixed delivery process SOP that can solve customer problems in a timely manner, including after-sales service, product customization service, packaging service, etc

Wait a minute. Please contact us to learn more. High quality service and quick response. Now I will introduce to you the advantages of our product.

Scene Diagram

RELATED PRODUCTS

Inquiry

Contact Us

Minimum order quantity of 50